With the recent success of Amazon’s Fallout series, power armor has come back into vogue as a seemingly logical extension of today’s combat technologies. Armored exoskeletons are certainly nothing new in science fiction, with depictions of similar technologies popping up in some of the world’s most beloved franchises. But between 2013 and 2019, the United States Special Operations Command, commonly known as SOCOM, aimed to pull this tech off of the big screen and inject it straight into combat – and while the effort ultimately failed to produce America’s first truly functional power armor suit, it did, nonetheless, help to shape the future of warfare.

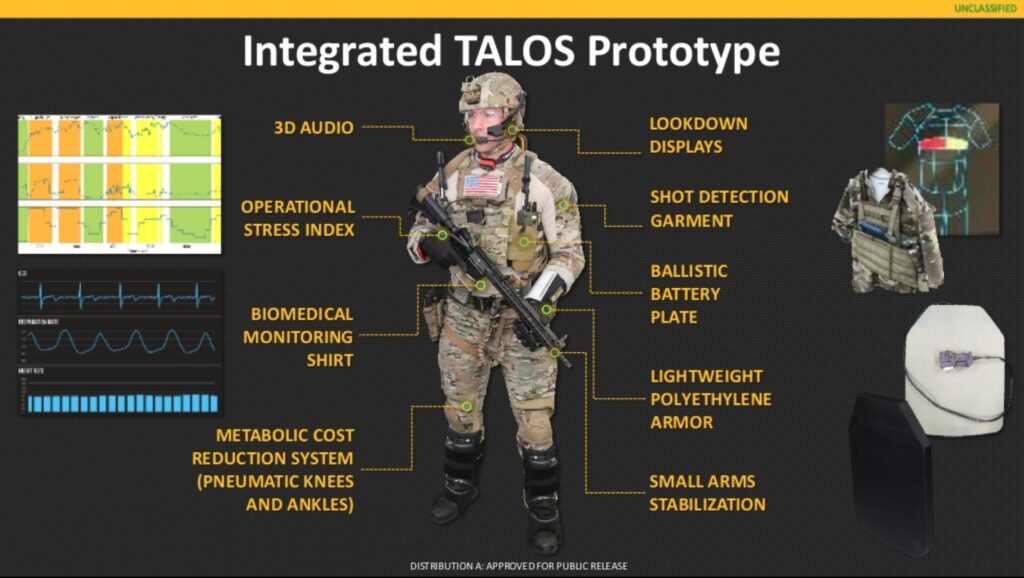

This effort, dubbed the Tactical Assault Light Operator Suit, or TALOS, could be thought of as a series of disparate technological programs, each focusing on different systems or technologies, that would ultimately be married together into a groundbreaking new capability.

As Colonel Alex MacCalman, the program’s chief engineer, put it: “The TALOS Project is a United States Special Operations Command (USSOCOM) initiative with the goal of increasing battlefield survivability, capability, situational awareness and lethality while operating in high risk environments, enabling new mission profiles, addressing historic casualty vulnerabilities, and decreasing the physical and cognitive load on the dismounted SOF operator.”

The end result, legendary SOCOM Commander Admiral William McRaven believed, would not necessarily equip every special operator in the field. Instead, it would be an extremely potent tool in SOCOM’s toolbox, meant to be used by operators tasked with some of the most dangerous operations. But like so many exotic technologies leveraged by special operators in the fight, the long-term implications of the TALOS effort extend far into the conventional force. After all, if SOCOM could get its power armor to work, it would only be a matter of time before other direct action elements of America’s armed forces came calling.

To overcome the massive engineering challenges associated with fielding real-world power armor, SOCOM took a different approach to its development. Conventional Defense acquisitions involve first identifying requirements and then identifying the right firms to meet those requirements. For TALOS, however, SOCOM established an “innovation cell” that could take a much more agile approach to sourcing hardware throughout both commercial and governmental sectors, using active-duty special operators as program advisors to ensure the tech being fielded met the needs of those who would be wearing it into the fight.

The TALOS program was divided into four overarching objectives, each of which encompassed a laundry list of its own technological efforts.

The first of those four objectives was increased survivability. It included efforts to improve the ballistic protection of helmets; provide more ballistic protection to vital areas of the body; create flexible but similarly protective armor for extremities; and find ways to reduce the operator’s visual, acoustic, and even electromagnetic signatures.

The second objective was to increase human performance. It included efforts to produce a powered or passively actuated combat suit to augment the operator’s strength and increase their carrying payload while minimizing reductions in mobility and range of motion and maximizing mission duration (with a target of 12 hours of operation without the need to recharge or refuel). This objective also aimed to regulate the operator’s body temperature while wearing the armor through the use of cooling systems, monitor the operator’s physical and even mental state, and even provide medical intervention like using tourniquets or administering aid through auto-injectors.

The third objective focused on increasing the operator’s situational awareness, and was divided into two sub-categories: video and audio awareness, and information awareness. The former included an entity disposition display (which could identify friendly, enemy, and civilian personnel as well as any potential objectives in a heads-up display), and an enhanced multi-spectral display for night vision operations. This sub-category also placed a focus on overcoming two of the biggest issues warfighters face when wearing large headgear: namely, minimizing any reduction in peripheral vision and ensuring the person inside the helmet maintains 3D audio awareness to triangulate the relative location of a sound’s origin.

Finally, the fourth objective was to increase surgical lethality, by augmenting the operator’s target detection capabilities and improving the lethal accuracy of those wearing the suit.

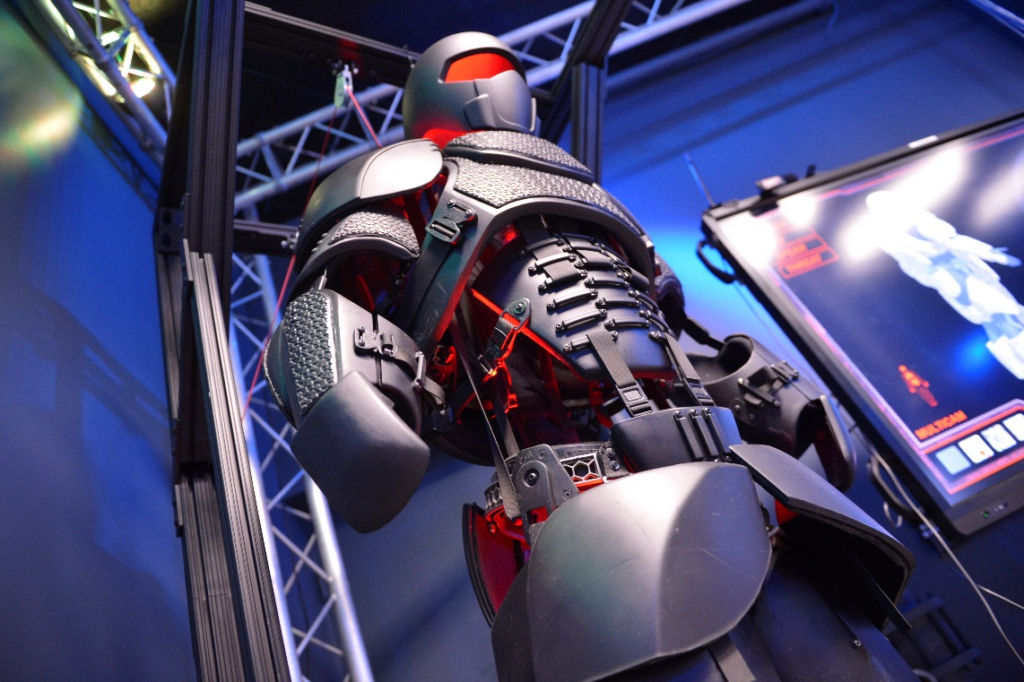

To accomplish these objectives, the program divided the suit into six functional areas, or modules, starting with the exoskeleton itself which was made of titanium and aluminum and included around 40 separate joints to retain as much mobility and flexibility as possible, with 14 of those joints supported by powered assistance. To make these joints function effectively, this area also included research and development into control-theory algorithms to match the operator’s intent to mechanical motion, as well as the sensors and control network required for the exoskeleton to function.

The second functional area, or module, was power – which arguably represents the biggest engineering challenge of the entire effort. This area included the development of what SOCOM called an “advanced battery solution,” as existing battery technology could not produce enough power for the duration needed for the TALOS to function. This module also included the development of a power distribution manager and a lab-insertion vehicle tether that would allow the suit to be powered by commercial generators or even nearby vehicles.

Related: SOCOM’s potential new firearm is a revolution

The next module, armor, was just as essential. As SOCOM explained at the time, standard helmets and body armor worn by special operators in the field only cover about 20% of the body. Using the same materials to cover an operator’s entire body, however, would add between 500 and 600 pounds. Yet, as added weight meant added power requirements, an emphasis was placed on finding lighter ways to provide greater protection.

This module included a focus on novel armor shapes that might protect against threats even better than the existing Special Operations Forces Personal Equipment Advanced Requirements (SPEAR) ballistic plates. The armor module included a ballistic helmet and mandible made of Ultra-High Molecular Weight Polyethylene (PE), improved helmet padding to absorb shocks, ceramic chest and lower abdomen plates, and an Ultra High Molecular Weight PE armor shell for the power enclosure.

The fourth function module was the Base Layer, which included a full-body sweat-wicking garment worn under the exoskeleton that was flame-resistant and launderable, as well as a thermal management system comprised of microtubing that would circulate warm or cold water around the operator’s body to compensate for extreme environmental conditions. The Base Layer module also included physiological monitoring, padding for the exoskeleton, and even soft armor for added protection below the ballistic plates.

The fifth module was C4I, short for Command, Control, Communications, Computing and Intelligence. This included all the data processing and storage requirements for the function of the armored suit, as well as two Harris 7800 radios for voice communications, an MPU-5 radio for data transmission, and a laundry list of software suites required to leverage the hardware found in other modules.

And finally, the sixth module was the Helmet (HMT) and Operator Interface (OI), which included the augmented reality display, motion tracking, microdisplays for inbound data like drone feeds, target acquisition assistance, and more. These functions would be controlled by a controller on the chest with between seven and nine buttons for various communications controls, an eight-button forearm controller with fingerprint reader, and another four-button wireless weapons controller.

When combined, the result was to be a game-changing piece of kit that would allow special operators to absorb a great deal of punishment, while performing superhuman feats of both strength and endurance. These suits would be rather clunky, but their combination of strength, protection, and improved situational awareness would have made the user into a veritable tank on the battlefield – one small enough to enter doorways, clear rooms, and more.

But as you can see looking back over that long list of technologies that needed to be matured to make the TALOS power armor work, SOCOM seemed to bite off more than it could chew. While the first prototype suits were initially meant to be fielded by 2018, repeated technical setbacks and program delays hamstrung the effort.

“We worked on integrating multiple radios, antennas, sensor feeds, and edge computing capabilities into a highly constrained suit design,” explained Maeve Garigan, CEO of the Roper Corporation and C4I team lead on the TALOS effort. “Not only was it highly constrained in size and weight, it was highly constrained on power. The exoskeleton, which supported the armor and moved the suit, was very power-intensive. Every ounce added to the suit had an outsized effect on the power needs and size of the exoskeleton. That’s just laws of physics.”

Related: Modern body armor was created by an irate pizza guy

The exoskeleton itself ballooned to over 800 separate components as it matured across four interactive prototypes, and early estimates suggested the overall TALOS power armor would require something in the neighborhood of three to five kilowatts of power to support 12 hours of operation, or enough to drive a Tesla Model 3 roughly 25 miles. This would require an incredibly energy-dense battery small and light enough to be carried on the bipedal suit – a technology that simply didn’t exist at the time.

“Exoskeletons consume power based on a wide variety of factors having to do with what function they are performing in operation and how much they weigh. For instance, running consumes more energy than standing still, and a heavier exoskeleton will consume more energy to move than a lighter exoskeleton,” explained Trish Aelker, Lockheed Martin exoskeleton program manager. “The power hurdle is particularly challenging because missions that are only expected to last minutes or hours can sometimes extend for days.”

While Aelker seemed optimistic, an analysis released by the Center for New American Security shortly thereafter was less so. Based on their findings, the current state of technology simply could not support the intense load-carrying capacity TALOS would require to meet SOCOM’s needs. Despite these challenges, SOCOM remained optimistic by May 2018, announcing that it intended to debut an operator clad in the operational exoskeleton within a year.

But less than a full year later, SOCOM acknowledged that its effort, while promising, was still a long way off from meeting its goals, in large part, because of those power limitations.

“When we get the exoskeleton here in a few months, we will have the best exoskeleton in the Department of Defense. It will not be something our operators will feel comfortable putting on a close [combat] environment today. So, moving, shooting, communicating in the face of enemy fire, not quite there yet,” James Smith, SOCOM’s acquisition executive told reporters.

And just a few months later, in February 2019, the TALOS power armor initiative formally died, with SOCOM’s release stating plainly that, “The prototype itself is not currently suitable for operation in a close combat environment.” But that wasn’t quite the end of this story.

While the overall effort failed to field a combined suit of power armor, the long list of developmental programs encompassed within that TALOS initiative did lead to several technological breakthroughs that each offered a great deal of value on their own. Among them was a lower-body exoskeleton that could dramatically increase both performance and endurance.

Related: Back-saving exosuits may someday be standard-issue gear for troops

“I have one operator that ran a four-minute mile. I forget how many miles but it was more than one,” SOCOM’s acquisition executive James Smith told Defense One. “This operator could not do a four-minute mile before that.”

The program also produced a new lightweight polyethylene body armor, new thermal management technologies, several new sensors meant to monitor an operator’s physical responses to their conditions, and even a new small-arms stabilization system that can help improve operators’ accuracy in combat.

“The full-body exoskeleton prototype to offload payload weight is currently not mature enough for SOF needs,” SOCOM spokesman Navy Lt. Phillip Chitty told Task & Purpose. “However, the knowledge gained informs the Services’ interest in exoskeleton technology for mobility and logistic applications.”

Like so many Defense programs that ultimately fail to manifest as operational capabilities, the inclination is to dismiss the five years and $80 million spent on TALOS as both time and money wasted, but reality is far more nuanced than that. The technologies developed and matured through this program have gone on to become the basis for some new programs and vital elements of others. Some of the most important, SOCOM contends, are in the realm of advanced communication links and augmented reality displays – technologies we continue to see mature through efforts like the Army’s Integrated Visual Augmentation System, or IVAS.

“We are using this TALOS project as a foundation to launch us into that research. And all the lessons we learned and the tech that we have seen is our opportunity to use that as a springboard,” Army Col. Alex MacCalman, director of SOCOM’s joint acquisition task force, said.

And who knows… Maybe one day in the not too distant future, we may yet see a true Fallout-style power armor system manifest. And when that day comes, such suits will all but certainly stand on the shoulders of efforts that came before – efforts like TALOS.

Read more from Sandboxx News

- The Cutts Compensator and the adoption of the Thompson SMG: A tale of Marine Corps corruption?

- Delving into the military urban legend of stress cards

- What’s all the ‘Hot Fuss’ about? The 20th anniversary of The Killers’ debut classic

- The special operations that paved the way for D-Day

- Video: America wants to use drone swarms to control the skies